Last time, I introduced the product lineup of the ABLIC's Automotive ICs. This time I would like to mention the Lithium-ion Battery Protection ICs / EDLC (Electric double-layer capacitor) Voltage Monitoring ICs for automotive use.

Recently, In the automotive industry, lead-acid car batteries are replaced with the Lithium-ion Batteries with the growing awareness for environmental conservation. And the importance of the battery is more and more rising because of the popularization of HV (hybrid vehicle) and EV (electric vehicle). And the safety of the batteries become much more important issues for the realization of the driver assistance and autonomous driving.

Under such circumstances, ABLIC prepares two products as a lineup of the Automotive Lithium-ion Battery Protection ICs / EDLC Voltage Monitoring ICs as shown in Table 1. These are the S-19192 Series which is for 12V battery and monitors both overcharge and overdischarge, and the S-19190 Series which is for EDLC cells and has cell-balancing which levels the voltage in each individual EDLC cell.

| Series Name | Features | Over-charge Detection | Over-discharge Detection | Self-test Function | Standalone Monitoring |

|---|---|---|---|---|---|

| Lithium-ion Battery Protection IC S-19192 | - Overdischarge detection operation is available. - For 3-serial to 6-serial cell pack | 2.5 to 4.5V | 1.5 to 3.0V | available | available |

| EDLC Voltage Monitoring IC S-19190 | - Cell balancing function is available. - Overcharge detection from 2.0V | 2.0 to 4.6V | - | - | available |

These protection ICs were developed mainly as the second protection ICs to back up the monitoring of the automotive batteries and capacitors. And they prepare the key functions, self-test (self-diagnosis) to improve the failure detection rate and standalone monitoring to ensure fail-safe operation at the time of failure (see right of the Table 1).

Fig.2 shows the flow of the Self-diagnosis function (Self-test). When you input the reset signal and the clock signal from MCU which is connected to the protection IC, it operates overcharge control circuit and overdischarge control circuit via self-test control circuit and outputs the execution result. If error signal is returned, it shows that the applicable circuit in the protection IC has broken.

In actual vehicles, when the ignition is switched on, the self-test is operated and enables to find a random failure of the protection IC before the vehicle is started to move.

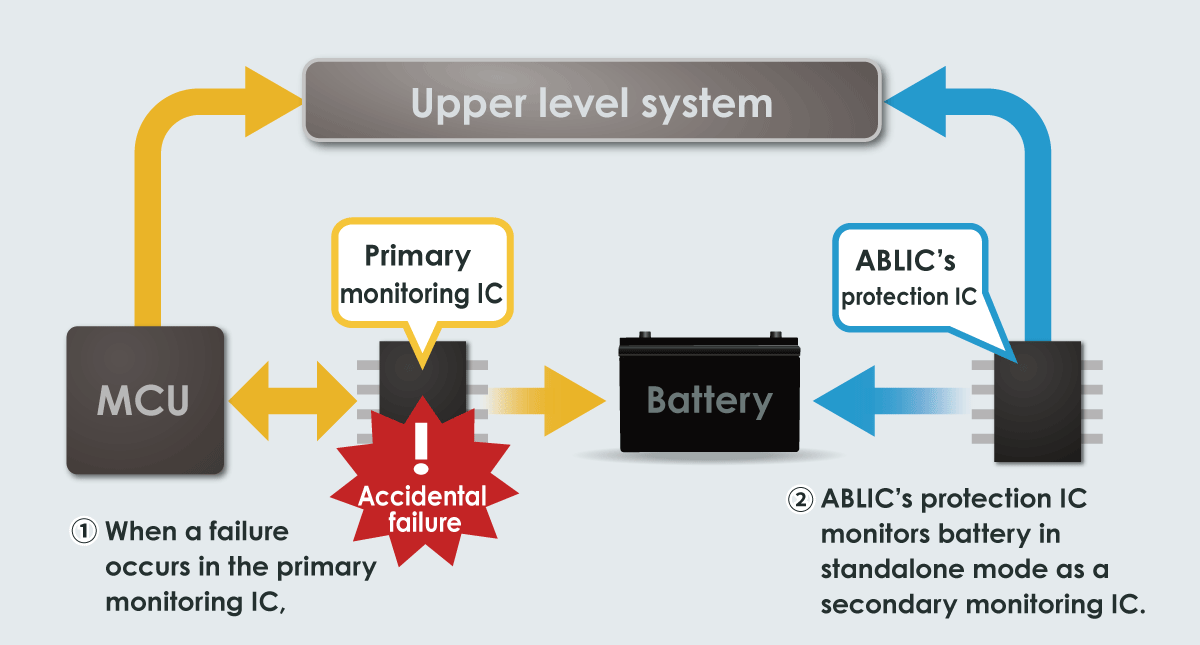

Fig.3 shows the flow of the standalone monitoring. Standalone monitoring is the function that is connected to upper level system directly and monitoring the battery constantly, independent from the MCU and without any operating software. When primary monitoring IC has an accident and lose control, ABLIC's protection IC is directly connected to upper level system as a secondary monitoring IC and continue to monitor the battery as shows in the right of Fig.3.

In addition to these features, the effort for ultra-low power consumption that all the ABLIC's production have in common is the major advantage of the company's protection IC. That is built on the integrated technology which is accumulated from transistor development sector to process management sector and optimized in the company. That is the advantage of IDM (Integrated Device Manufacturers) who handle every step of the process, from chip design to manufacturing.

Under such circumstances, ABLIC has been started the process improvement, testing enhancement for developing automotive products and added features introduced above and so on and finally launched their Automotive ICs.

As shown in Fig.4, the era of the vehicles with HV and EV will move to driver assistance and finally go to autonomous driving in the near future. Looking these changes, ABLIC says that they will enhance and improve the functions and the qualities of the protection ICs more and more. I would like to keep watching not only the ABLIC's protection ICs but also all their automotive analog ICs.